BENEFIT FROM FLEXIBILITY THROUGH COMPATIBILITY

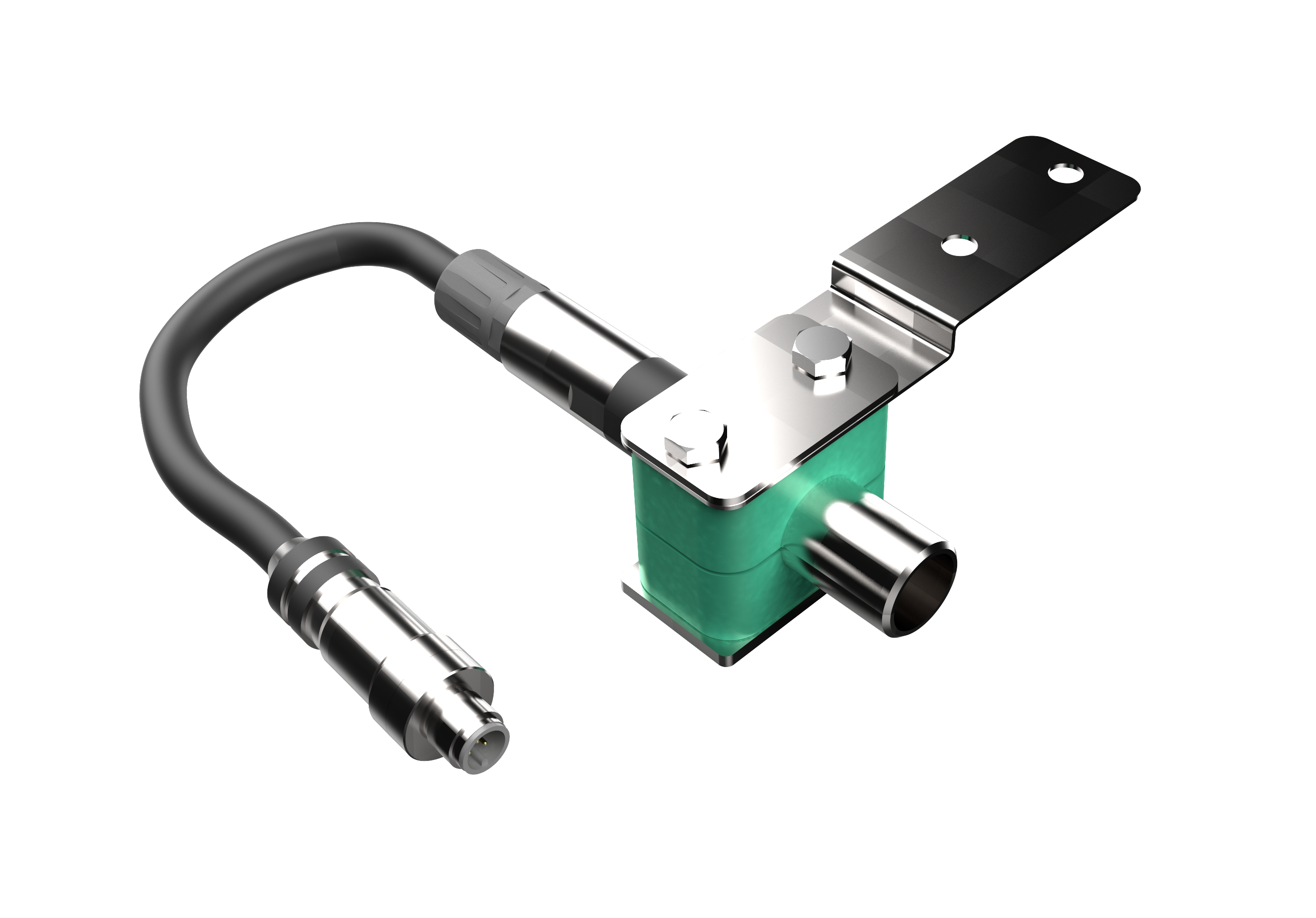

The Sonic-Ski Plus has firmly established itself as a flexible sensor technology in road construction. Thus, the sensor can be changed from ground to rope sensing in just one action and is therefore a real time miracle with changing references. As an ultrasonic sensor that scans the height reference without contact, it is completely wear-free and therefore far superior to other technologies in terms of durability. Disturbing influences such as rain, stones or edges are immediately detected and faded out to guarantee the installation of an absolutely even surface.

The digital inclination sensor can be optimally integrated into the CAN network of the system and thus complements the levelling system with a powerful inclination control for paving slopes. The state-of-the-art technology systematically suppresses shocks and accelerations and thus makes your levelling work many times more precise. Thanks to the minimal cable installation, the number of wear parts and the associated potential sources of error are reduced to a minimum.

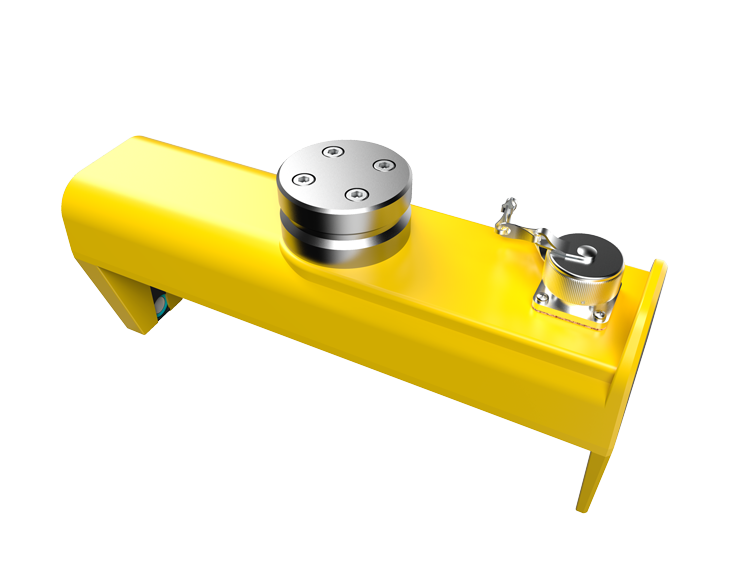

As a combination, MOBA-matic and the sensor solution Big Sonic-Ski with up to 4 ultrasonic sensors are absolutely unbeatable! Thanks to a span of 27'8", even long ground waves are completely levelled out and eliminated. This unique feature ensures an exceptionally flat surface and makes the system not only the most precise technology on the market, but also an absolutely groundbreaking solution. Welcome to road construction of the future!

25% higher accuracy through the fourth Sonic-Ski Plus.

Larger ground sections will be smoothed out.

Milling waves are detected and smoothed out.

Provides a long distance virtual level reference.

Several temperature sensors are installed along the path of the material, e.g. at the front of the paver and in the paver's hopper, to continuously measure the temperature of the material from the hopper to the screed. The temperature is then displayed in real time on the MOBA-Matic II, so that asphalting can be better controlled and quality-relevant factors can be reacted to at an early stage.